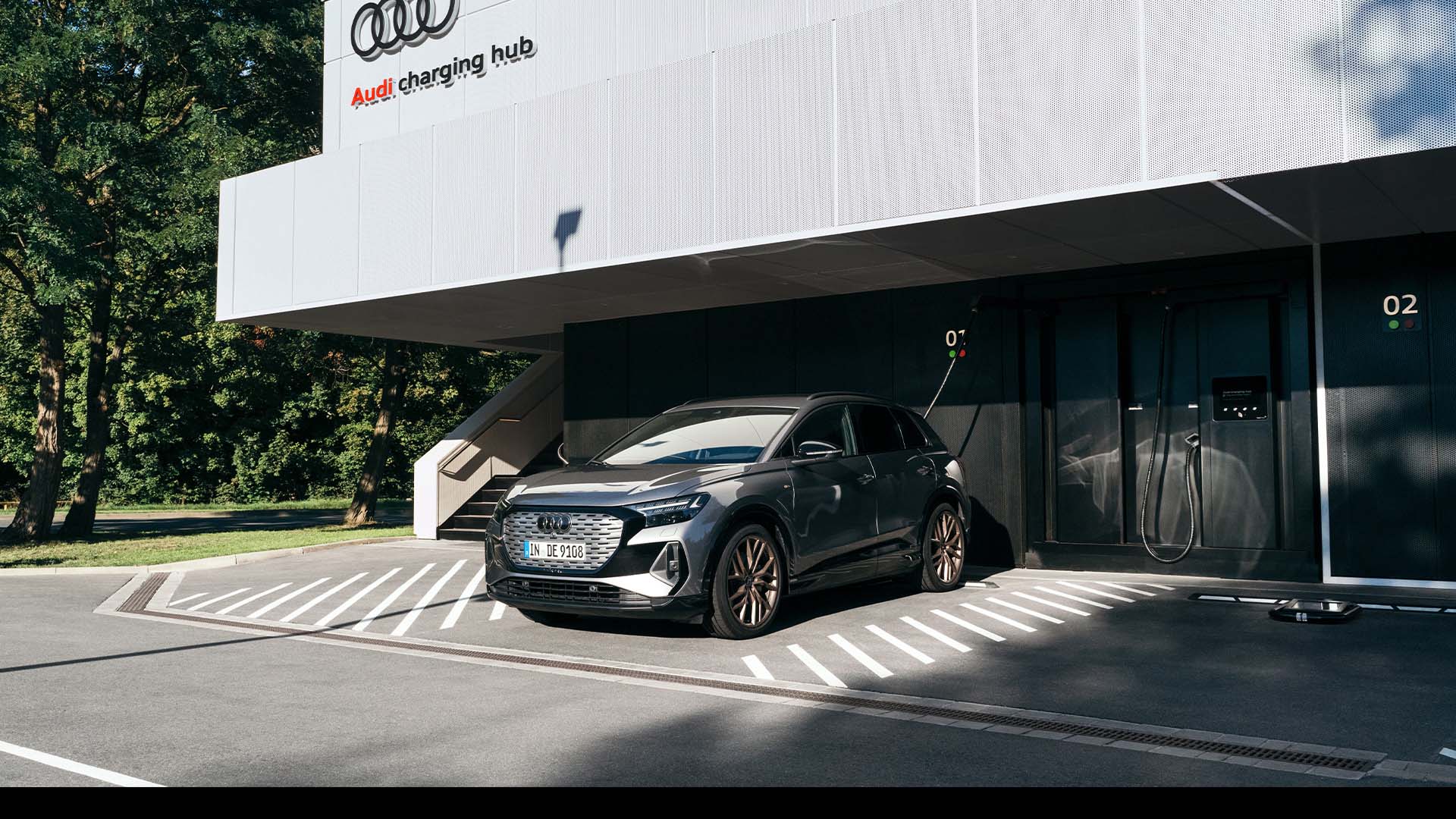

The Audi charging hub is a pilot project for the charging infrastructure of premium electric mobility.

“Battery development is incredibly exciting right now.”

German chemist Maximilian Fichtner does research on the battery technology of the future. He believes that efficient batteries are key to the success of electromobility.

Professor Fichtner, storage batteries are the most important part of an electric vehicle. Which one is the best for this purpose?

A battery that combines the best properties of storage capacity, fast loading, low cost, safety and sustainability, depending on the vehicle and its purpose.

In the luxury class, a long range is what counts. In the compact class, the battery should be significantly less expensive, but it does not need to offer quite as much storage capacity.

There is only limited space for a battery in an electric vehicle. What design should you aim for in order for a battery of the same size to offer even more storage capacity?

Some manufacturers are working with the so-called "cell-to-pack design", or "cell-to-body design", i.e. battery packs are no longer made up of chocolate bar-sized cells but are instead plank-sized. Such larger units require less packaging material, thus providing more space for the actual storage material. They achieve an integration density of more than 70 percent, while normal batteries only achieve about 50 percent.

EV manufacturers aiming to develop their own batteries can take these technological leaps into account right from the outset. After all, it’s not about the individual battery cell, but rather about building cells that are as space-saving and yet as large as possible.

What kind of progress do you expect to see in batteries in the coming years?

We expect to make progress in leaps and bounds. The first battery packs from two Chinese manufacturers have been announced for 2023, enabling a range of more than 1000 kilometers. At the same time, they are expected to recharge a range of 700 kilometers in less than 10 minutes.

As a researcher, I am surprised myself by the dynamics of this development. This would be a great leap in battery technology, which isn’t even based on fancy new battery chemistry, but rather on technological measures.

"EV manufacturers aiming to develop their own batteries can take these technological leaps into account right from the outset."

Prof. Dr. Maximilian Fichtner researches the battery technology of the future in Germany.

Prof. Dr. Maximilian Fichtner

Charging power is often neglected. What is the connection between charging speed and battery technology?

That's true, because you rarely drive 600 kilometers at a stretch. So it's important for large batteries to be able to recharge quickly. At the end of the day, that is what it really is all about. When you can charge your EV battery from 10 to 80 percent in just ten minutes, it’s game over for the combustion engine.

There are materials that allow batteries to be charged more quickly, while others will take longer. Technically speaking, lithium ions move from the cathode to the anode when charging, and the anode stores lithium ions when the battery is charged.

Currently, a graphite layer is added to the anode. There are battery manufacturers who want to use silicon-carbon composites instead, as they can be charged much faster, even at low temperatures. There is a lot of development potential as far as materials are concerned. By changing the material of the anode alone, the cell as a whole will gain 30 percent more storage capacity. So there are still incredible breakthroughs ahead of us.

But apart from that, if you want to charge a 60-kWh battery in ten minutes, you will need an EV charger with a charging power of 360 kW. So right now, it’s not the battery power that is limited, but rather the EV charging infrastructure.

When it comes to smartphones, the performance of the battery decreases significantly after two or three years of frequent use. How long is the service life of an EV battery?

Such batteries are very different, and smartphones are actually designed to be replaced after three years. In an electric vehicle, the battery control system is much more intelligent, and the battery is protected from overheating and other harmful influences in many ways, such as intelligent charge management.

Studies with newer vehicles show that after five years, 95 percent of the battery's residual capacity is usually still available. The traction battery in an electric vehicle is designed to complete 2000 full cycles. For example, 2000 times a range of 500 kilometers makes 1 million kilometers of capacity.

After these 2000 full cycles, the battery reaches a threshold of 80 percent residual capacity, which is considered the end of a battery's life. However, the battery is then far from broken and can still do a good job for another ten years in a stationary storage system of photovoltaic or wind power plants, for instance.

“The traction battery in an electric vehicle is designed to complete 2000 full cycles.”

Maximilian Fichtner

Gigafactories for battery production are being built around the world. Will there be sufficient raw materials for the production of cells in the coming years or decades?

Currently, there is enough quantity available. However, production capacities have not yet been adapted to the rapidly increasing demand, so that bottlenecks may occur in some areas. We researchers are trying to remedy this situation by, for example, completely eliminating cobalt from the new batteries and by partially replacing lithium with sodium in the future. This is something that will significantly reduce the potential shortage of raw materials.

Eleven gigafactories for batteries are currently being planned in Germany, which is unparalleled. There is huge potential to do the right thing. The crucial question is: Will these gigafactories only produce cells, or will they cover the entire system?

How important are recycling processes for used batteries in this context?

Very important. It is estimated that from around 2034, half of the raw materials needed will already be recycled. There are currently 38 battery recycling plants in Europe that are developing new processes and expanding their capacities. When the large volumes of EV batteries need to be recycled in the mid-2030s, they have to be prepared.

The battery accounts for a large part of the cost of an electric vehicle. What needs to happen to bring these costs down?

For this purpose, it is necessary to use less expensive materials, i.e. raw materials that are common, occur worldwide, and can be mined uncritically. In addition, manufacturers must develop new energy- and time-saving processes.

Apart from the shift to more sustainable materials, cost reduction is the megatrend in battery production. This applies everywhere: less space, less energy, less time. There's a lot going on in development, and it's happening faster than you may sometimes think. Battery development is incredibly exciting right now.